Life Sciences

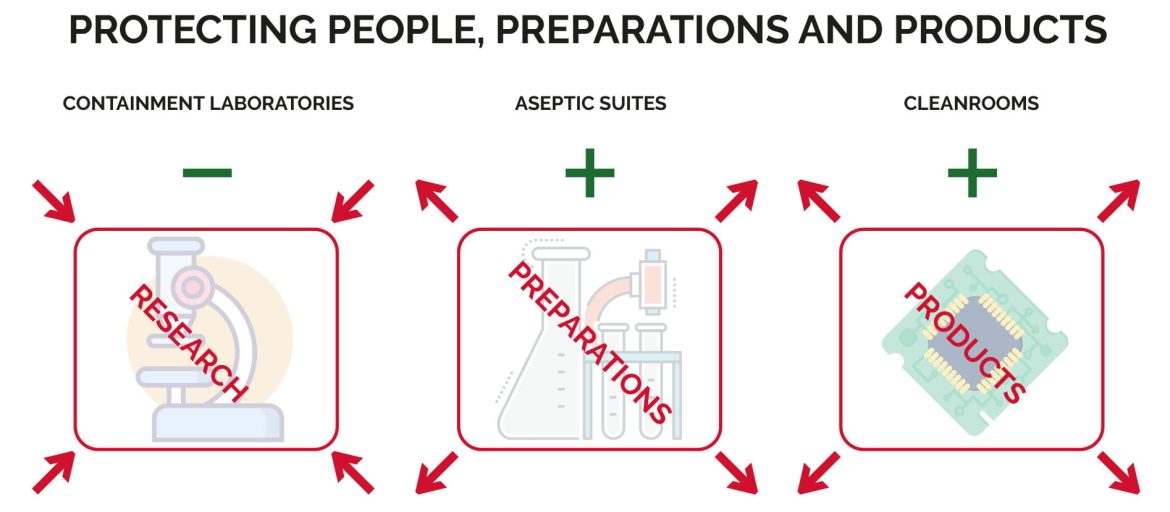

Containment laboratories, aseptic suites and cleanrooms

Medical Air Technology’s solutions for cleanrooms, aseptic areas and containment laboratories help hospitals and universities move forward to fulfil their vision of developing healthcare technologies to diagnose, treat and combat diseases.

Whether you want a total turnkey design-and-build installation, an upgrade, refurbishment, reclassification or conversion, MAT can apply its expertise to designing and installing the right specialist environment for your needs.

Designing the controlled environment of a cleanroom, aseptic suite or laboratory is a complex challenge that requires a detailed understanding of the rules and restrictions governing operation and validation.

It must also be a comfortable workplace for operatives - despite the need for increased air changes and greater airflow, no one in the room should be working in a draught or other situation causing discomfort.

MAT has an advanced understanding of the importance of room structure and the way airflow operates.

This is vital when conceptualising and designing safe and compliant facilities including:

- MHRA licensed aseptic suites (radiopharmacies, stem cell laboratories, cytotoxic pharmacies, gene therapy, TPN, IVF, etc)

- ACDP-compliant containment laboratories built to CTSA and LPS1175 security standards (microbiology, forensic science, tropical disease research, immunology and vaccinology, biotechnology, veterinary medicine, etc)

- BS EN ISO 14644-1 compliant cleanrooms (pharmaceutical manufacturing, electronics, aerospace, optical and research)

Containment laboratories

Containment Level/Category 2 and 3

Category 2 (CAT2) or Containment Level 2 (CL2) is the biosafety level required by laboratories working with agents associated with human diseases that pose a moderate health hazard. Examples include Legionella pneumophila and Pseudomonas aeruginosa.

Specialist airflow design ensures that no dangerous pathogens are able to escape from the laboratory.

Category 3 (CAT3) or Containment Level 3 (CL3) is the highest containment level in common use in the UK. This level of containment is required when handling human pathogens that may be transmitted via inhalation, that often have a low infectious dose to produce effects and that can cause serious or life-threatening disease. These Schedule 5 pathogens include HIV, hepatitis B, yellow fever, and rabies.

In a CAT3 lab, a constant inflow of air means that the facility is maintained under negative pressure and that the airflow is always away from the operator, so they are not exposed to infection. Any contaminated air is exhausted through the safety cabinets or a bypass or separate extract system, depending on the size of the room.

Work with animal pathogens is classified into groups 2-4. The Department for Environment, Food and Rural Affairs (DEFRA) determines the classification of animal pathogens under the Specified Animal Pathogen Order (SAPO). Genetically modified organisms are categorised under the Genetically Modified Organisms (Contained Use) Regulations and require facilities similar to those specified under COSHH.

In the era of bioterrorism, consideration may need to be given to the Anti-terrorism, Crime and Security Act 2001 Part 7: Security of Pathogens and Toxins Upon completion. In addition, a CL3 laboratory must be constructed and commissioned in accordance with Advisory Committee on Dangerous Pathogens (ACDP) guidance and the Control of Substances Hazardous to Health (COSHH) regulations.

Features of CAT2 and CAT3 laboratories:

CAT2

- Microbiological safety cabinets

- Access restrictions and security

- Surfaces impervious to water, acids and agents

- CO2 incubators

- Safe storage of biological agents

- Optional mechanical ventilation

- Air management systems

- Centrifuges, fridges and freezers

CAT3

- Fully sealed environments

- Constant negative pressure

- Security and IT legal requirements

- Controlled fumigation process

- Safe storage of biological agents/pathogens

- Motorised isolation

- HEPA extract and change facilities

- UPS power supply

- Lone worker safety systems

- HSE observation requirements

Aseptic suites and licensed premises

An aseptic suite is a type of cleanroom used for the manufacture of pharmaceutical drugs. It has to be a microorganism-free space to avoid contamination. It achieves this through specialist HVAC and room design, which ensures that no contaminants are able to enter the suite or licensed premises.

Radiopharmacies, stem cell laboratories, cytotoxic pharmacies, gene therapy, total parenteral nutrition (TPN) and in vitro fertilisation (IVF) all require aseptic conditions.

Features of aseptic suites:

- Bespoke air conditioning systems

- GRP and specialist finished doors

- BMS integration

- Double framed light fittings, IP65 seals

- Pharmacy isolators with grade A airflow

- Security, storage and SOP-compliant

- Interlocked system doors/pass throughs

- Specialist finishes

Cleanrooms

A cleanroom is a controlled environment where pollutants like dust, airborne microbes and aerosol particles are filtered out of the external ambient air to provide the cleanest area possible. Specialist airflow design ensures that this is achieved.

Outside air is first driven to a filter system, where it is cleaned and decontaminated by the filters (HEPA or ULPA). The filtered air is then forced into the cleanroom. Contaminated air within the cleanroom is forced outside the room by registers, or it is recirculated back into the filters, and the process starts again. Most cleanrooms employ positive pressure to keep the outside air out so unfiltered dirty air is not drawn in.

It is also important to note that the design, layout and placement of cleanrooms has a significant impact on processes, behaviours and communications. A good design proactively supports processes such as flow, visual management, standard work, and excellence in workplace organisation, whereas a bad design may actually create waste and make flow more difficult.